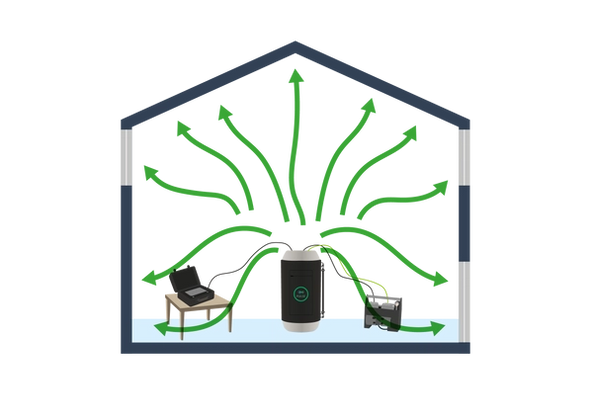

A single Pulse air receiver, compressor and control unit is designed to be carried by one person enabling easy access to the site.

Air receivers feature carry handles as well as shoulder straps and have side pockets where all the necessary cables and hoses are stored neatly between jobs.